Infrastructure

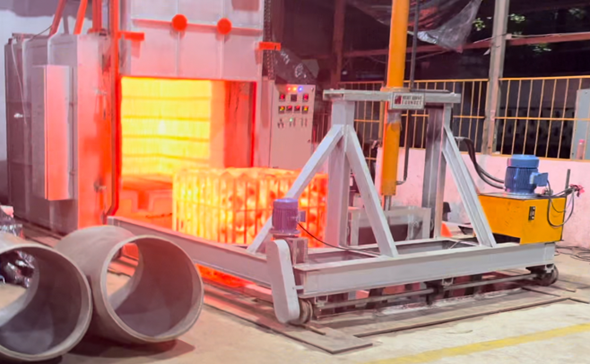

Our Advanced Manufacturing Facilities

Equipped with modern machinery, our facilities ensure precision, efficiency, and world-class quality in every operation.

TEE HOT PRESSING

ELBOW HOT PRESSING

ELBOW SAW WELDING

ELBOW HOT MANDREL FORMING MACHINE

EQUIPMENT FABRICATION

COLD FORMING ELBOW MACHINE

COLD FORMING TEE MACHINE